PMMA, PC, PS, PVC, MS various panel material difference

Time:2022-03-22Views:5432First, polycarbonate Polycarbonate (PC)

Advantages: Dissive toughness: dimensional stability; limit: poor chemical resistance, difficult moldability, low fatigue, polycarbonate (PC) has excellent impact strength,

High heat resistance and good dimensional stability. The polycarbonate (PC) is once the first thermoplastic of these properties. Although water, minerals, and organic acids are stable,

Dissolved in an aromatic hydrocarbon, dissolved in a chlorinated solvent, and is decomposed by strong. Polycarbonate (PC) also has good electrical properties. The polycarbonate (PC) is reinforced by the glass fiber.

It can further increase its intensity and size stability. 40% glass fiber reinforced polycarbon ester (PC) can reduce thermal expansion coefficient to 1.0 in / in / degrees

F x 10e-5 (1.8 cm / cm / degrees C x 10e-5), which is lower than most of the thermoplastic plastic and some metal. Its tensile modulus increased by 5 times. Its flexural, tensile and pressure

The shrinkage is doubled. Its modal shrinkage is further reduced to make it possible to make very precise parts. High-fluid polycarbonate (PC) can produce cross-section thickness less than

0.04 inches (1 mm) thickness parts. This high-fluid material has good dimensional stability. Its intensity and rigidity are similar to standard polycarbonate (PC). However, it is tiered

The character will be reduced than standard liquid polycarbonate (PC). PC anti-impact and weather resistance, anti-aging is better than organic glasses, generally used in indoor organic glass, outdoor needs long

Heavy resistance to high temperature with PC.

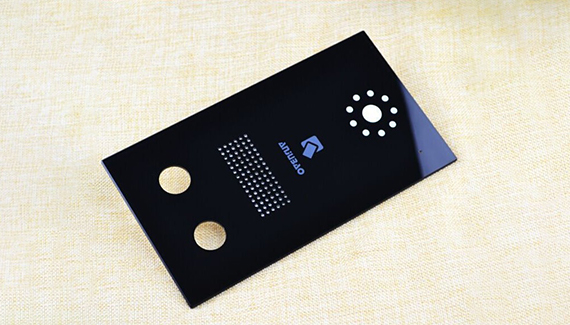

Acrylic panel physical map / customizable acrylic touch panel

Second, plexiglass acrylic (PMMA)

Advantages: transparent / dyed

Weather resistance

: Electrical (insulation) characteristics

Restriction: poor impact resistance

Fire-flame retardant and other extreme materials opaque

Characteristics of plexiglass:

1 height transparency. Organic glass is currently the best polymer transparent material, with a light transmittance of 92%, which is higher than the translutectivity of the glass. The sun lights called the artificial sun

The lamp is done because the quartz can completely transmit ultraviolet light. Ordinary glass can only pass through 0.6% ultraviolet rays, but the organic glass can pass through 73%.

2 High mechanical strength. The relative molecular mass of the organic glass is approximately 2 million high molecular compounds, and the chain forming the molecule is very soft, so the strength of the organic glass is

High, anti-stretching and impact resistance than ordinary glass 7

~ 18 times. There is an organic glass that has been heated and tensile, wherein the molecular segment is arranged very in order to make the toughness of the material have significantly improved. Nail nail

In this plexiglass, even if the nail is penetrated, the organic glass does not produce cracks. This organic glass is also broken after the bullet breaks down. Therefore, stretching

Organic glass can be used as a bulletproof glass and is also used as a seat cover on the military aircraft.

3 weight. The organic glass is 1.18kg / dm3, the same size material, the weight is only half of ordinary glass, metal aluminum (belonging to light metal)

43% of.

4 is easy to process. The organic glass can not only be cut by the lathe, the drilling machine is drilled, but also uses acetone, chloroform, etc., can be bonded into various shapes of various shapes, and can also be blow molded.

Methods of injection, extruded plastic molding are machined into a large-colored article such as aircraft cockpit, small to denture and dentistry.

Third, organic glass (acrylic), PC endurance plate, PS organic board, MS board difference

First: Organic glass (acrylic) is: extruded plate and cast plate, extruded plate identification, transparency, with the most primitive identification method, fire burning, fire

Flame, no smoke, with bubbles, can pull out the filaments when fire extinguishing. The identification of the cast plate is: the transparency is higher, when combined with fire, smoke-free, there is air bubble, there is a snoring sound,

Diffility when extinguishing.

Second: PC endurance board, identification method is: high transparency, good impact, can't be rotten, fire with fire is basically burned, flame retardant, and will take part of black smoke.

Third: PS organic board, identification method is: transparency is general, and it will be numb in the reflective. It is more crisp and easy to rupture. There will be a snoring sound in the ground. Use fire combustion

Produce a large amount of black smoke.

Fourth: MS board, identification method is: transparency is general, and there will be numbers in the reflective. A large amount of black smoke is generated when combir is burned with fire. Basically close to the PS board, but flexibility and processing performance is better than the PS organic board.

Hotline:18688756555

Mailbox: Shichao66@dgjskj.net

Website: www.modeljr.com

Address: 3rd Floor, No. 10, Shan Road, Shatou Community, Chang'an Town, Dongguan, Guangdong, China

Copyright @ 2021 Dongguan Jucheng Technology Co., Ltd. All rights reserved. 粵ICP備2022007545號

Sitemap